Sehloohong sa kajeno, re tla fumana phapang lipakeng tsa ribbon blender le paddle mixer.

Ribbon blender ke eng?

Ribbon blender ke moralo o otlolohileng oa sebopeho sa U o loketseng ho kopanya phofo, lino le granules, 'me o ka kopanya le thepa e nyane haholo ka bongata. Kaho, lik'hemik'hale tsa temo, lijo, li-polymers, meriana, le liindasteri tse ling kaofela li ka rua molemo ho motsoako oa ribone. Bakeng sa ts'ebetso e sebetsang hantle le tlhahiso, ribone blender e fana ka likhetho tse fapaneng tsa ho kopanya tse ka senyehang haholo.

Paddle mixer ke eng?

Ha ho na gravity mixer ke lebitso le leng la motsoako oa marang-rang. Hangata e sebelisoa ho kopanya phofo le lino, hammoho le granular le powders. Lijo, lik'hemik'hale, chefo e bolaeang likokoanyana, phepelo ea lijo, libeteri le lihlahisoa tse ling kaofela li koahetsoe ke eona. E na le motsoako o phahameng oa ho nepahala o sebetsanang le likaroloana 'me o o kopanya hantle, ho sa tsotellehe matla a eona a khoheli, boholo, kapa palo ea likaroloana. E hlahisa ho arohana ha karolo ka ho eketsa lisebelisoa tsa ho arola. Motsoako o ka etsoa ka lisebelisoa tse sa tšoaneng, ho akarelletsa le 316L, 304, 201, carbon steel, joalo-joalo.

Ho phaella moo, sehlahisoa se seng le se seng se na le likarolo tsa sona.

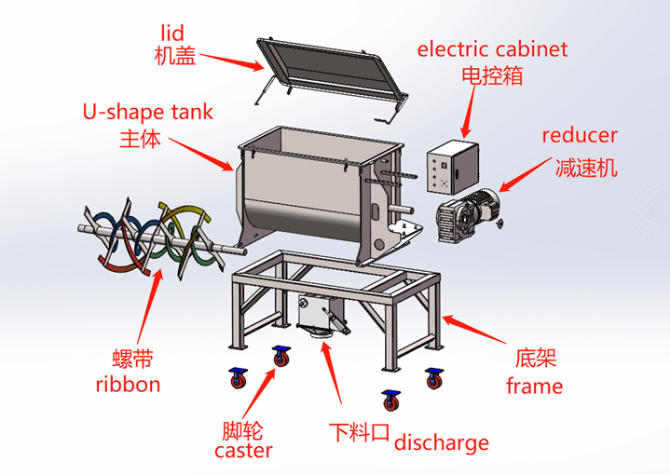

Likarolo tsa Ribbon Blender:

- Khokahano e cheselitsoeng hantle e teng likarolong tsohle.

-Bokahare ba tanka bo bentšitsoe ka botlalo, bo na le lente le shaft.

- Tšepe e sa hloekang 304 e sebelisoa likarolong tsohle.

- Ha o kopanya, ha ho na li-angles tse shoeleng.

- E na le sebopeho se chitja se nang le sekoaelo sa lesale la silicone.

- E na le marang-rang a sireletsehileng, lehare, le mabili.

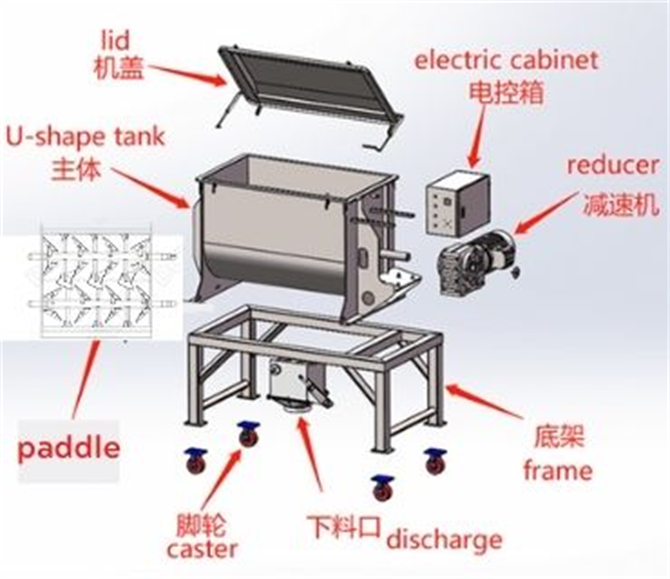

Likarolo tsa Paddle Mixer:

1.e sebetsang haholo: potoloha morao 'me u lokolle lisebelisoa ka litsela tse fapaneng. Nako ea ho kopanya ke metsotso e 1 ho isa ho e 3.

2.Bophahamo bo phahameng ba ho kopanya: Hopper e tlatsitsoe ka ho sebelisa moralo o kopanetsoeng le li-shafts tse potolohang, tse hlahisang 99% ea ho kopanya.

3.Masala a tlaase: sekoti sa ho lahla se bulehileng se nang le lekhalo la 2-5 mm feela pakeng tsa li-shafts le lerako.

4.No Leakage: Sekoti se pota-potileng le lesoba la ho lahla li sirelelitsoe ke moralo o ntseng o emetse patent.

5.E hloekile ka ho feletseng: mokhoa o ts'oaretsoeng ka ho feletseng le o betliloeng bakeng sa hopper ea ho kopanya ntle le likarolo tsa ho tiisa tse kang li-screws kapa linate bakeng sa hopper ea ho kopanya.

6.Stainless steel e sebelisoa ho pholletsa le mochine, ntle le setulo sa ho jara, ho fana ka ponahalo e boreleli.

Sebopeho sa mixer ka 'ngoe:

Ntle le agitator, likarolo tsohle lia tšoana.

Ribone blender

Motsoako oa marang-rang

Melao-motheo ea ts'ebetso ea e 'ngoe le e' ngoe e fapane:

A na u ne u tseba hore ho na le li-ribbon agitators tse peli ka har'a ribone blender?

Ho sebetsa hantle le ho sebetsa ha ribbon blender ke eng?

-Theribone blendere na le kamore e bōpehileng joaloka U le moferefere oa ribone bakeng sa motsoako o leka-lekaneng oa motsoako. Moferefere o ka hare oa helical le moferefere o ka ntle oa helical a etsa lente la ribone. Ha o jara metsoako, lente le ka hare le jara metsoako ho tloha bohareng ho ea ka ntle, ha lente le ka ntle le jara metsoako ho tloha mahlakoreng a mabeli ho ea bohareng. Ribbon blender e fokotsa nako ea ho kopanya ha e ntse e ntlafatsa sephetho sa ho kopanya.

-A motsoako oa likooae na le marotholi. Li-paddles ka li-angles tse fapaneng li nka lisebelisoa ho tloha tlase ho ea holimo ho tanka e kopanyang. Mefuta e fapaneng ea boholo le density ea likarolo li na le litlamorao tse fapaneng ho hlahiseng sephetho sa motsoako o ts'oanang. Bophahamo ba sehlahisoa bo senyehile 'me bo kopantsoe ka mokhoa o latellanang ka li-paddles tse pota-potileng, ho qobella karolo e' ngoe le e 'ngoe hore e phalle ka tanka ea ho kopanya ka potlako le ka matla.

E boetse e fapana ho ea ka thepa le tšebeliso:

Ribone blendere atisa ho sebelisoa bakeng sa motsoako o omileng o tiileng, thepa ea metsi 'me e sebelisoa lits'ebetsong tse latelang:

Indasteri ea meriana: ho kopanya li-powders le granules.

indasteri ea lik'hemik'hale: metsoako ea phofo ea tšepe, chefo e bolaeang likokoanyana, meriana e bolaeang limela, le tse ling tse ngata.

Indasteri ea ho lokisa lijo: lijo-thollo, metsoako ea kofi, phofo ea lebese, phofo ea lebese le tse ling tse ngata.

Indasteri ea kaho: li-preblends tsa tšepe, joalo-joalo.

Indasteri ea polasetiki: ho kopanya li-masterbatches, ho kopanya li-pellets, li-powders tsa polasetiki, le tse ling tse ngata.

Li-polymers le liindasteri tse ling.

Liindasteri tse ngata le tsona li se li sebelisa li-blender tsa ribone.

Motsoako oa marang-range na le thuso liindastering tse ngata tse kang:

Indasteri ea lijo- lihlahisoa tsa lijo, metsoako ea lijo, li-additives tsa lijo, AIDS e sebetsanang le lijo mafapheng a fapaneng, le litlhare tse mahareng, tse ritehang, li-enzyme tsa likokoana-hloko, thepa ea ho paka lijo le tsona li sebelisoa haholo.

Indasteri ea temo- Chefo e bolaeang likokoanyana, manyolo, lijo le meriana ea bongaka ba liphoofolo, lijo tse tsoetseng pele tsa liphoofolo tse ruuoang lapeng, tlhahiso e ncha ea ts'ireletso ea limela, mobu o lenngoeng, tšebeliso ea likokoana-hloko, manyolo a tlhaho le botala ba lehoatata.

Indasteri ea lik'hemik'hale- Epoxy resin, lisebelisoa tsa polymer, lisebelisoa tsa fluorine, lisebelisoa tsa silicon, nanomaterial, le indasteri e meng ea rabara le ea polasetiki ea lik'hemik'hale; Metsoako ea silicon le li-silicates le lik'hemik'hale tse ling tse sa sebetseng le lik'hemik'hale tse fapaneng.

Indasteri ea Battery- Thepa ea Battery, lithium battery anode material, lithium battery cathode material, le carbon material raw material production.

Indasteri e felletseng- Thepa ea brake ea koloi, lihlahisoa tsa ts'ireletso ea tikoloho ea semela, lisebelisoa tsa tafole tse jeoang, jj.

Eo e ka ba phapang pakeng tsa mixer ea paddle le ribbon blender. Ka tšepo, e tla u thusa ho khetha sutu e ntle ka ho fetisisa bakeng sa lihlahisoa tsa hau.

Nako ea poso: Feb-23-2022